The Role of CAE Simulation in Enhancing Product Performance

CAE Simulation (Computer-Aided Engineering Simulation) is a technology used to simulate and analyze the physical behavior of a product or system under various conditions.

In today's competitive world, businesses are continuously striving to improve the quality and efficiency of their products. One of the most significant advancements in product design and development is Computer-Aided Engineering (CAE) simulation. This technology has revolutionized industries by enabling engineers and designers to virtually test and analyze products before they are physically created. By using CAE simulation, companies can identify potential problems, optimize designs, and improve product performance, all while saving time and reducing costs. In this blog, we will explore the role of CAE simulation in enhancing product performance and how it can be leveraged to create superior products.

Understanding CAE Simulation and Its Importance

Before diving into how CAE simulation enhances product performance, it’s important to understand what it is and why it has become an essential tool for product development. CAE simulation is a computer-based technology that allows engineers and designers to simulate and analyze various physical conditions and behaviors of a product during its design phase. These simulations can range from stress testing, fluid dynamics, heat transfer, vibration analysis, and much more.

CAE simulation is valuable because it offers the ability to test a product's performance under various real-world conditions without having to build multiple prototypes. This means that companies can catch design flaws and inefficiencies early in the development process, making it easier and more cost-effective to refine and optimize designs. The ability to simulate different scenarios also helps predict how a product will behave in the real world, which ultimately leads to higher-quality products that perform better and last longer.

Note - For businesses looking to integrate CAE simulation into their product development process, partnering with a reliable third-party software supplier can make all the difference. Whether you are optimizing designs, enhancing product performance, or reducing time-to-market, CAE simulation offers a powerful solution. Contact a trusted provider today to explore the benefits of CAE simulation and elevate your product development process to new heights.

Reducing Development Time and Costs

One of the primary benefits of using CAE simulation is its ability to significantly reduce both development time and costs. Traditionally, engineers had to build physical prototypes and test them repeatedly to understand how they would perform under different conditions. This process could take weeks, months, or even longer, and it was often expensive to produce multiple versions of a product for testing.

With CAE simulation, the need for physical prototypes is greatly reduced. Engineers can use digital models to simulate how a product will react to various stresses, forces, and environmental factors. This not only saves time but also eliminates the cost of creating physical prototypes. By identifying potential problems in the virtual environment, designers can make necessary adjustments to the design early in the process, avoiding costly changes later in development or production.

Moreover, CAE simulation helps optimize product designs by enabling multiple iterations to be tested virtually. This ability to evaluate numerous variations quickly leads to faster product development, allowing businesses to bring products to market sooner than ever before.

Improving Product Quality and Performance

Another key advantage of CAE simulation is its ability to improve product quality and performance. During the design phase, engineers can use CAE simulation to test how products will react to various conditions, such as pressure, temperature changes, or environmental stress. This allows them to identify potential weak spots, material limitations, or other factors that could negatively impact the product's performance.

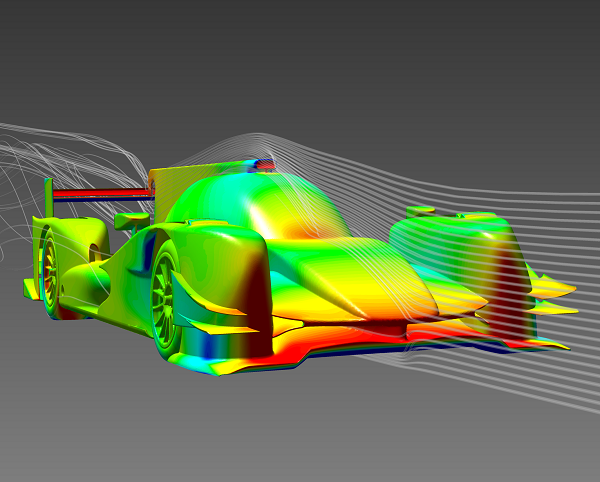

For example, in the automotive industry, CAE simulation can be used to evaluate the aerodynamics of a car, ensuring that it operates efficiently and safely at high speeds. Similarly, in the aerospace industry, CAE simulation is used to simulate the effects of turbulence and stress on aircraft components, helping to ensure that the product can withstand extreme conditions while maintaining safety standards.

By using CAE simulation to detect and correct design flaws, engineers can create products that are stronger, safer, and more reliable. These improvements lead to enhanced product performance, which not only satisfies customers but also boosts the reputation of the company producing the product.

Enabling Complex Designs and Innovations

CAE simulation also opens the door to complex, innovative designs that may have been previously difficult to achieve using traditional methods. Engineers can experiment with new materials, shapes, and structures without worrying about the feasibility of physical testing. By simulating how these innovations will perform in real-world conditions, CAE simulation makes it possible to push the boundaries of design and engineering.

This capability is particularly valuable in industries where performance and safety are paramount. In the medical device industry, for example, CAE simulation allows designers to develop more advanced devices that are both functional and safe. The simulation software can test how a device will interact with human tissue, how it will perform over time, and how it can be optimized for minimal discomfort or risk to the patient.

Moreover, CAE simulation makes it easier for companies to implement cutting-edge technologies and design principles into their products. From advanced composite materials in aerospace to novel heat exchange technologies in electronics, CAE simulation allows for testing and validation without the high costs and risks associated with traditional physical testing.

Optimizing Energy Efficiency and Sustainability

In today’s environmentally-conscious world, sustainability and energy efficiency are critical considerations for many industries. CAE simulation plays a crucial role in optimizing these factors during product development. Engineers can use simulation tools to assess how a product will impact energy consumption, waste, and environmental sustainability throughout its lifecycle.

For instance, in the building and construction industry, CAE simulation can be used to optimize the design of energy-efficient HVAC systems or to improve the insulation properties of a building's structure. Similarly, in the automotive industry, CAE simulation can help design more fuel-efficient vehicles by analyzing the impact of different materials and designs on energy usage.

By incorporating energy efficiency and sustainability into the design process through CAE simulation, companies can develop products that not only perform well but also contribute to a greener, more sustainable future.

Enhancing Collaboration and Communication Across Teams

CAE simulation also improves collaboration and communication between different teams involved in the product development process. Engineers, designers, and other stakeholders can share digital models, simulations, and test results, making it easier to work together and align their goals. This collaborative approach helps ensure that everyone is on the same page and working toward a common objective.

By using CAE simulation tools that allow for real-time feedback and adjustments, companies can streamline the decision-making process and avoid misunderstandings that might arise from traditional methods. This increased level of communication helps teams address potential issues quickly and efficiently, which further contributes to the overall success of the product development process.

Conclusion

The role of CAE simulation in enhancing product performance cannot be overstated. It helps businesses reduce development time and costs, improve product quality, enable complex innovations, and optimize energy efficiency and sustainability. By integrating CAE simulation into the design and development process, companies can create better products, faster, and at a lower cost, ultimately gaining a competitive edge in the market. As industries continue to embrace digital transformation, CAE simulation will play an increasingly critical role in shaping the future of product development and performance.

For more insightful articles related to this topic, feel free to visit bipmessenger.com

What's Your Reaction?