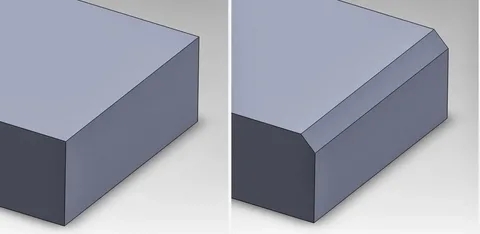

Chamfer vs Fillet: Real-World Examples and Their Applications

A chamfer refers to a sloped or beveled edge that replaces a 90-degree angle with a straight cut. Chamfers are typically employed for aesthetic purposes,

Designers and engineers often encounter the terms "chamfer" and "fillet" in their workflows. Understanding their differences, practical uses, and applications in real-world scenarios can improve functionality and aesthetic appeal in projects. In this article, we explore the distinctions between chamfers and fillets, discuss their pros and cons, and delve into real-world examples where each is applied.

Understanding the Basics: What Are Chamfers and Fillets?

A chamfer refers to a sloped or beveled edge that replaces a 90-degree angle with a straight cut. Chamfers are typically employed for aesthetic purposes, safety considerations, or functionality where sharp edges could create stress concentrations or pose a hazard. They are common in mechanical engineering, woodworking, and construction to improve product design.

A fillet, on the other hand, is a rounded edge that smoothens a corner or transitions between two surfaces. Fillets are used to reduce stress concentration, improve material flow in molds, and enhance the durability of components. Found frequently in aerodynamics, automotive parts, and machining, fillets create softer and more natural transitions. Both features play distinct roles based on design requirements and functional objectives.

Applications of Chamfers in Real-World Scenarios

Chamfers are often used in mechanical design to ease assembly processes. For instance, screws and bolts frequently feature chamfered edges at their tips to help guide them into threads more easily. This design consideration significantly reduces assembly time and enhances the precision of components in mechanical systems.

In construction and woodworking, chamfers are utilized to soften sharp edges for safety while maintaining a clean and angular appearance. Chamfered edges in furniture or countertops reduce the likelihood of injury and give designs a sleek and modern aesthetic. Their geometric precision also facilitates better alignment during assembly.

Applications of Fillets in Practical Use Cases

Fillets find extensive use in aerospace and automotive engineering, where stress concentration can be a critical concern. Rounded edges improve the load distribution in structural components, reducing the likelihood of material failure. For example, fillets are essential in aircraft wings and automotive chassis to enhance aerodynamics and durability.

In injection molding and 3D printing, fillets play a vital role by preventing material buildup at corners and improving mold flow. Rounded edges help ensure that materials fill the molds evenly, reducing the risk of defects such as voids or weak points in the final product. Fillets are crucial for creating durable and efficient components.

Chamfer vs Fillet: When to Choose Each?

The decision to use a chamfer or a fillet often depends on design intent and functional requirements. Chamfers are preferred when sharp transitions are needed, such as in electrical components or cutting tools, where angular precision is critical. Fillets, conversely, are ideal for designs requiring durability, stress reduction, or smoother transitions.

From an aesthetic perspective, chamfers provide a modern and industrial look, while fillets convey softness and elegance. This difference influences their use in consumer products, with chamfers dominating high-tech gadgets and fillets more common in ergonomic designs like handles or household appliances.

Hybrid Designs: Combining Chamfers and Fillets

Certain designs benefit from combining chamfers and fillets to leverage the strengths of both. In mechanical components, a chamfer might guide assembly while a fillet reduces stress at the joint. This combination is often seen in gears, shafts, and other rotating machinery.

In architectural design, combining chamfers and fillets can create visually striking yet functional elements. For instance, a staircase railing may feature chamfered edges for a modern look and filleted corners to enhance user safety and comfort. These hybrid approaches demonstrate the versatility of these features in various industries.

Understanding the distinctions and applications of chamfer vs fillet is essential for achieving optimal design and functionality in engineering, manufacturing, and design projects. Whether prioritizing structural integrity or aesthetic appeal, the strategic use of chamfers and fillets enables more efficient, safe, and visually pleasing designs.

What's Your Reaction?